| |

Building Code Requirements

Spacing of Wires

Inwalls and slabs other than concrete joist construction, the principal reinforcement shall not be spaced farther apart than 3 thimes the wall or slab thickness, nor more than 18 inches (457 mm)....................................................................ACI-318-89 Section 7.6.5

In slabs where principle reinforcement extends in one direction only, shrinkage and temperature reinforcement at right angles to the principle reinforcement shall be spaced not farther apart than 5 times the salb thickness, nor more than 18 inches (457 mm)...............................................ACI 318-89 Section 7.12.8

Minimum Reinforcement Requirements

For shrinkage and temperature reinforcement in structurally reinforced slabs* :

| 1. |

Slabs where welded wire fabric with fy = 65,000 psi (448 MPa) ; (ACI 318 assigns fy = 60,000 psi (414 MPa) but makes provision for the use of higherfy provided the stress corresponds to a strain of 0.35%). Use ratio of reinforcement-to-gross concrete area of 0.0018............................................................. |

| 2. |

Slabs where welded wire fabric exceeds 65,000 psi (448 MPa), use 0.0018 x 60,000 when fy exceeds 60,000 psi (414 MPa), material shall be measured at a yield strain of 0.35%, but not less than 0.0014... |

ACI 318-89 Section 7.12.2.1 (b) ; (c)

For minimum wall reinforcement:

| |

Wall designs require the following minimum reinforcement ratios when reinforced with welded wire fabric (wire sizes not larger than W31 or D31)

(MW200 or MD200)..............................................

Vertical -0.0012...................................................

Horizontal -0.0020................................................ |

ACI 31889 Section 14.3.2;3

Splices

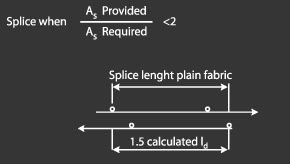

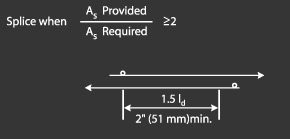

The splice length in inches shall be the largest of the values shown in the figures below.

| (a) |

|

but not less than 1 space + 2"(51 mm) nor 6" (152 mm) minimum Note : overhangs must be added to the splice length for plain fabric.

| (b) |

|

Plain Wire Fabric Splice Lengths

Design Methods and Details.

Designs shall not be based on yield strength (fy) in excess of 80,000 psi (552 MPa), except for prestressing tendons.......

ACI 318.89 Section 9.4

Welded wire fabric ASTM yield Strengths are specifield at 0.50 percent strain. ACI specifiles use of maximum design yield strengths of 60,000 psi (414 MPa) unless fy is measured at 0.35 percent strain.....................................................

ACI 318-89 Section 3.5.3.4;5.3.5.4.2 |

|

|

|

|

|

|

|

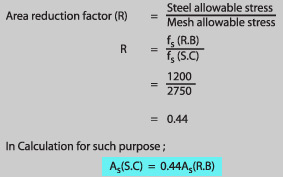

| SUBSTITUTION OF |

| S.C. WIRE MESH FOR MILD STEEL BARS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

R.C. PAVEMENT ....AASHTO M-32

Reinforcement for concrete reinforcements is designed to hold cracks that result from flexural stress*v tightly cloded. The assumption is that the reinforcing steel must be strong enough to drag both ends of individual slab over the subgrade toward its center. The idea expressed as aformular becomes;

|

|

|

|

|

|

|

|

|

|

| |

|

|

| |

Specifications and Properties |

|

| |

| ตารางที่ 1 ขนาดและเกณฑ์ความคลาดเคลื่อนของลวด SIDE A PERMISSIBLE VARIATION (ข้อ 3.1)

มอก. 737-2531

| สัญลักษณ์ของลวดยืนและลวดขวาง |

เส้นผ่านศูนย์กลาง/มิลลิเมตร |

เกณฑ์ความคลาดเคลื่อนของเส้นผ่านศูนย์กลาง/มิลลิเมตร |

พื้นที่หน้าตัด ระบุ ตาราง มิลลิเมตร |

| CDR2 |

2.0 |

|

3.14 |

| CDR2.3 |

2.3 |

|

4.16 |

| CDR2.6 |

2.6 |

|

5.31 |

| CDR3 |

3.0 |

|

7.07 |

| CDR3.3 |

3.3 |

|

8.56 |

| CDR3.6 |

3.6 |

|

10.18 |

| CDR4 |

4.0 |

|

12.57 |

| CDR4.3 |

4.3 |

|

14.53 |

| CDR4.6 |

4.6 |

+/- 0.1 |

16.63 |

| CDR5 |

5.0 |

|

19.64 |

| CDR5.3 |

5.3 |

|

22.07 |

| CDR5.6 |

5.6 |

|

24.64 |

| CDR6 |

6.0 |

|

28.29 |

| CDR6.5 |

6.5 |

|

33.20 |

| CDR7 |

7.0 |

|

38.50 |

| CDR7.5 |

7.5 |

|

44.20 |

| CDR8 |

8.0 |

|

50.29 |

| SIZE NUMBER |

DIAMETER(MM.) |

PERMISSIBLE VARIATION |

SECTION (mm2) |

|

|

|

|

TABLE 3 Minimum Requirements of steel Wires in Welded Wire Fabric

WELDED PLAIN WIRE FABRIC

ASTM A185, CSA G30.5 |

|

|

|

|

| Wire Size |

Tensile Strength psi |

Yield Strength psi |

Weld Shear Strength |

|

| W1.2% & over |

75,000

(517 MPa) |

65,000

(448 MPa) |

35,000

(241 MPa) |

|

under

W1.2 |

70,000

(483 MPa) |

56,000

(386 MPa) |

|

|

|

|

|

|

|

|

|

|

|

WELDED DEFORMED WIRE FABRIC ASTM A497, CSA G30.15

|

|

|

|

| Wire Size |

Tensile Strength psi |

Yield Strength psi |

Weld Shear Strength |

|

D31

thru D4 |

80,000

(552 MPa) |

70,000

(483 MPa) |

35,000

(241 MPa) |

|

under

D4 |

80,000

(552 MPa) |

70,000

(483 MPa) |

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

| |

S.C.STANDARD SQUARE MESH

| WIRE |

SECTION AREA |

SECTION AREA AT DIFFEREUT SPACINGS (mm2/m) |

| (mm) |

(mm2) |

15 |

20 |

25 |

30 |

| 4.0 |

12.6 |

84 |

63 |

50 |

- |

| 5.0 |

19.6 |

131 |

98 |

78 |

65 |

| 6.0 |

28.3 |

189 |

142 |

113 |

94 |

| 6.5 |

33.2 |

221 |

166 |

133 |

94 |

| 7.0 |

38.5 |

257 |

193 |

154 |

128 |

| 7.5 |

44.2 |

295 |

221 |

177 |

147 |

| 8.0 |

50.3 |

335 |

252 |

201 |

168 |

| 8.5 |

56.7 |

378 |

284 |

227 |

189 |

| 9.0 |

63.6 |

424 |

318 |

254 |

212 |

| 10.0 |

78.5 |

523 |

393 |

314 |

262 |

| 11.0 |

95.0 |

633 |

475 |

380 |

317 |

| 12.0 |

113.1 |

754 |

566 |

452 |

377 |

S.C.STANDARD RECTANGULAR MESH

WIRE

(mm) |

10 x 20 |

10 x 30 |

15 x 20 |

Section Area

(mm2/m) |

Section Area

(mm2/m) |

Section Area

(mm2/m) |

| Long |

Cross |

Long |

Cross |

Long |

Cross |

| 4.0 |

126 |

63 |

126 |

42 |

84 |

63 |

| 5.0 |

196 |

98 |

196 |

65 |

131 |

98 |

| 6.0 |

283 |

142 |

283 |

94 |

189 |

142 |

| 6.5 |

332 |

166 |

332 |

111 |

221 |

166 |

| 7.0 |

385 |

196 |

385 |

128 |

257 |

193 |

| 7.5 |

442 |

221 |

442 |

147 |

295 |

221 |

| 8.0 |

503 |

252 |

503 |

168 |

335 |

252 |

| 8.5 |

567 |

284 |

567 |

189 |

378 |

284 |

| 9.0 |

636 |

318 |

636 |

212 |

424 |

318 |

| 10.0 |

785 |

393 |

785 |

262 |

523 |

393 |

| 11.0 |

950 |

475 |

950 |

317 |

633 |

475 |

| 12.0 |

1131 |

566 |

1131 |

377 |

754 |

566 |

|

|

| |

|

|

|